[ Mon, Jul 28th ]: The Motley Fool

[ Mon, Jul 28th ]: WSAZ

[ Mon, Jul 28th ]: BGR

[ Mon, Jul 28th ]: WTVO Rockford

[ Mon, Jul 28th ]: Seeking Alpha

[ Mon, Jul 28th ]: Jerusalem Post

[ Mon, Jul 28th ]: ScienceAlert

[ Mon, Jul 28th ]: Fox News

[ Mon, Jul 28th ]: Associated Press

[ Mon, Jul 28th ]: The Jerusalem Post Blogs

[ Mon, Jul 28th ]: Cleveland.com

[ Mon, Jul 28th ]: CBS News

[ Mon, Jul 28th ]: The Globe and Mail

[ Mon, Jul 28th ]: Organic Authority

[ Mon, Jul 28th ]: Wrestle Zone

[ Mon, Jul 28th ]: gizmodo.com

[ Mon, Jul 28th ]: Fadeaway World

[ Mon, Jul 28th ]: The Weather Channel

[ Mon, Jul 28th ]: The New York Times

[ Mon, Jul 28th ]: Phys.org

[ Mon, Jul 28th ]: yahoo.com

[ Mon, Jul 28th ]: The Cool Down

[ Mon, Jul 28th ]: Forbes

[ Mon, Jul 28th ]: Chicago Tribune

[ Mon, Jul 28th ]: KCBD

[ Mon, Jul 28th ]: Impacts

[ Mon, Jul 28th ]: World Socialist Web Site

[ Mon, Jul 28th ]: IBTimes UK

[ Sun, Jul 27th ]: The New Indian Express

[ Sun, Jul 27th ]: Local 12 WKRC Cincinnati

[ Sun, Jul 27th ]: The Telegraph

[ Sun, Jul 27th ]: Good Housekeeping

[ Sun, Jul 27th ]: GovCon Wire

[ Sun, Jul 27th ]: The Jerusalem Post Blogs

[ Sun, Jul 27th ]: Forbes

[ Sun, Jul 27th ]: The Financial Express

[ Sat, Jul 26th ]: Reuters

[ Sat, Jul 26th ]: The News International

[ Sat, Jul 26th ]: KTVU

[ Sat, Jul 26th ]: Forbes

[ Sat, Jul 26th ]: Futurism

[ Sat, Jul 26th ]: lbbonline

[ Sat, Jul 26th ]: Phys.org

[ Sat, Jul 26th ]: NJ.com

[ Sat, Jul 26th ]: The Cool Down

[ Sat, Jul 26th ]: HuffPost Life

[ Sat, Jul 26th ]: The Jerusalem Post Blogs

[ Sat, Jul 26th ]: Live Science

[ Sat, Jul 26th ]: The Motley Fool

[ Sat, Jul 26th ]: thedispatch.com

[ Sat, Jul 26th ]: Salon

[ Sat, Jul 26th ]: WTVO Rockford

[ Sat, Jul 26th ]: yahoo.com

[ Sat, Jul 26th ]: ZDNet

[ Sat, Jul 26th ]: Impacts

[ Sat, Jul 26th ]: BBC

[ Sat, Jul 26th ]: Seeking Alpha

[ Sat, Jul 26th ]: The Globe and Mail

[ Sat, Jul 26th ]: London Evening Standard

[ Sat, Jul 26th ]: The New Indian Express

[ Fri, Jul 25th ]: NBC Washington

[ Fri, Jul 25th ]: 13abc

[ Fri, Jul 25th ]: CBS News

[ Fri, Jul 25th ]: The Observer, La Grande, Ore.

[ Fri, Jul 25th ]: reuters.com

[ Fri, Jul 25th ]: Upper

[ Fri, Jul 25th ]: Investopedia

[ Fri, Jul 25th ]: Associated Press

[ Fri, Jul 25th ]: The Motley Fool

[ Fri, Jul 25th ]: Cleveland.com

[ Fri, Jul 25th ]: Newsweek

[ Fri, Jul 25th ]: KOAT Albuquerque

[ Fri, Jul 25th ]: The Cool Down

[ Fri, Jul 25th ]: Fox News

[ Fri, Jul 25th ]: Space.com

[ Fri, Jul 25th ]: Forbes

[ Fri, Jul 25th ]: Fortune

[ Fri, Jul 25th ]: The Boston Globe

[ Fri, Jul 25th ]: Leader-Telegram, Eau Claire, Wis.

[ Fri, Jul 25th ]: Madrid Universal

[ Fri, Jul 25th ]: moneycontrol.com

[ Fri, Jul 25th ]: Ghanaweb.com

[ Fri, Jul 25th ]: Impacts

[ Fri, Jul 25th ]: Daily Record

[ Fri, Jul 25th ]: newsbytesapp.com

[ Thu, Jul 24th ]: WABI-TV

[ Thu, Jul 24th ]: WAFF

[ Thu, Jul 24th ]: HELLO! Magazine

[ Thu, Jul 24th ]: St. Louis Post-Dispatch

[ Thu, Jul 24th ]: thetimes.com

[ Thu, Jul 24th ]: Impacts

[ Thu, Jul 24th ]: The Hill

[ Thu, Jul 24th ]: Action News Jax

[ Thu, Jul 24th ]: Fox News

[ Thu, Jul 24th ]: NBC 6 South Florida

[ Thu, Jul 24th ]: Live Science

[ Thu, Jul 24th ]: sportskeeda.com

[ Thu, Jul 24th ]: Defense News

[ Thu, Jul 24th ]: Seeking Alpha

[ Thu, Jul 24th ]: CNET

[ Thu, Jul 24th ]: yahoo.com

[ Thu, Jul 24th ]: London Evening Standard

[ Thu, Jul 24th ]: The 74

[ Thu, Jul 24th ]: Ukrayinska Pravda

[ Thu, Jul 24th ]: Rhode Island Current

[ Thu, Jul 24th ]: The Decatur Daily, Ala.

[ Thu, Jul 24th ]: Foreign Policy

[ Thu, Jul 24th ]: Florida Today

[ Thu, Jul 24th ]: MassLive

[ Thu, Jul 24th ]: Business Today

[ Thu, Jul 24th ]: The Cool Down

[ Thu, Jul 24th ]: WFXT

[ Thu, Jul 24th ]: Newsweek

[ Thu, Jul 24th ]: Associated Press Finance

[ Thu, Jul 24th ]: Milwaukee Journal Sentinel

[ Thu, Jul 24th ]: The Straits Times

[ Thu, Jul 24th ]: The Sun

[ Thu, Jul 24th ]: newsbytesapp.com

[ Thu, Jul 24th ]: Forbes

[ Thu, Jul 24th ]: BBC

[ Thu, Jul 24th ]: WFTV

[ Thu, Jul 24th ]: TechCrunch

[ Thu, Jul 24th ]: The Michigan Daily

[ Thu, Jul 24th ]: moneycontrol.com

[ Wed, Jul 23rd ]: People

[ Wed, Jul 23rd ]: Today

[ Wed, Jul 23rd ]: ABC News

[ Wed, Jul 23rd ]: WESH

[ Wed, Jul 23rd ]: ABC

[ Wed, Jul 23rd ]: Seeking Alpha

[ Wed, Jul 23rd ]: Politico

[ Wed, Jul 23rd ]: yahoo.com

[ Wed, Jul 23rd ]: Atlanta Journal-Constitution

[ Wed, Jul 23rd ]: The Motley Fool

[ Wed, Jul 23rd ]: reuters.com

[ Wed, Jul 23rd ]: Telangana Today

[ Wed, Jul 23rd ]: Fox News

[ Wed, Jul 23rd ]: Newsweek

[ Wed, Jul 23rd ]: Medscape

[ Wed, Jul 23rd ]: The Scotsman

[ Wed, Jul 23rd ]: Deseret News

[ Wed, Jul 23rd ]: Forbes

[ Wed, Jul 23rd ]: KWCH

[ Wed, Jul 23rd ]: ThePrint

[ Wed, Jul 23rd ]: New Jersey Monitor

[ Wed, Jul 23rd ]: moneycontrol.com

[ Wed, Jul 23rd ]: Milwaukee Journal Sentinel

[ Wed, Jul 23rd ]: Daily Express

[ Tue, Jul 22nd ]: Fox 13

[ Tue, Jul 22nd ]: newsbytesapp.com

[ Tue, Jul 22nd ]: CNBC

[ Tue, Jul 22nd ]: Forbes

[ Tue, Jul 22nd ]: The Hill

[ Tue, Jul 22nd ]: KBTX

[ Tue, Jul 22nd ]: Detroit News

[ Tue, Jul 22nd ]: Fox News

[ Tue, Jul 22nd ]: The Independent

[ Tue, Jul 22nd ]: NBC DFW

[ Tue, Jul 22nd ]: Phys.org

[ Tue, Jul 22nd ]: Post-Bulletin, Rochester, Minn.

[ Tue, Jul 22nd ]: STAT

[ Tue, Jul 22nd ]: Associated Press

[ Tue, Jul 22nd ]: Newsweek

[ Tue, Jul 22nd ]: Space.com

[ Tue, Jul 22nd ]: Channel 3000

[ Tue, Jul 22nd ]: Tacoma News Tribune

[ Tue, Jul 22nd ]: The 74

[ Tue, Jul 22nd ]: Orlando Sentinel

[ Tue, Jul 22nd ]: Auburn Citizen

[ Tue, Jul 22nd ]: Impacts

[ Tue, Jul 22nd ]: BBC

[ Mon, Jul 21st ]: AFP

[ Mon, Jul 21st ]: ESPN

[ Mon, Jul 21st ]: al.com

[ Mon, Jul 21st ]: Forbes

[ Mon, Jul 21st ]: WFRV Green Bay

[ Mon, Jul 21st ]: Organic Authority

[ Mon, Jul 21st ]: Fox News

[ Mon, Jul 21st ]: gadgets360

[ Mon, Jul 21st ]: CNN

[ Mon, Jul 21st ]: USA TODAY

[ Mon, Jul 21st ]: NBC New York

[ Mon, Jul 21st ]: CBS News

[ Mon, Jul 21st ]: Seeking Alpha

[ Mon, Jul 21st ]: NJ.com

[ Mon, Jul 21st ]: Reuters

[ Mon, Jul 21st ]: Stateline

[ Mon, Jul 21st ]: Philadelphia Inquirer

[ Sun, Jul 20th ]: ABC

[ Sun, Jul 20th ]: Pacific Daily News

[ Sun, Jul 20th ]: The Cool Down

[ Sun, Jul 20th ]: The New Indian Express

[ Sun, Jul 20th ]: WFTV

[ Sun, Jul 20th ]: CBS News

[ Sun, Jul 20th ]: The Daily Dot

[ Sun, Jul 20th ]: Forbes

[ Sun, Jul 20th ]: The Jerusalem Post Blogs

[ Sun, Jul 20th ]: Impacts

[ Sun, Jul 20th ]: The Citizen

[ Sun, Jul 20th ]: Business Today

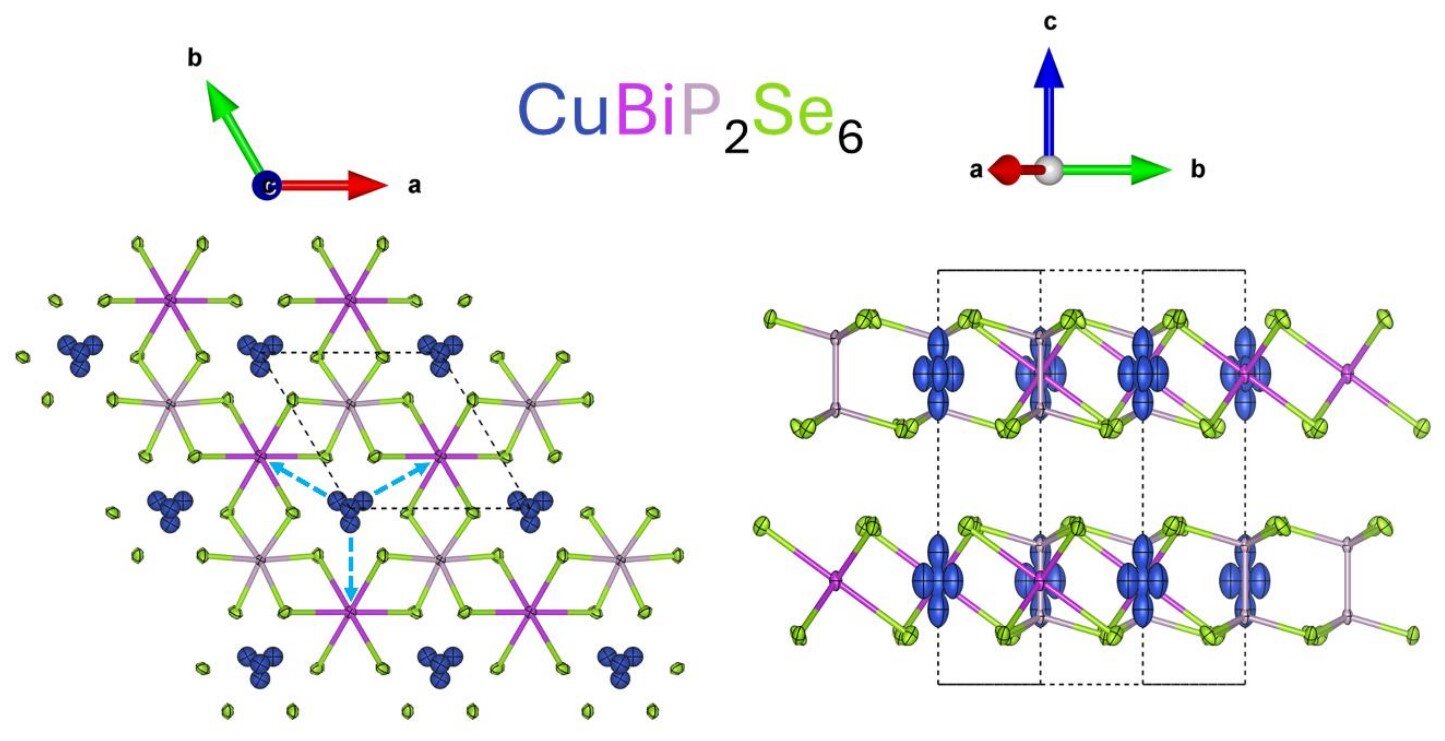

New method predicts promising 2D materials for next-generation electronics

🞛 This publication is a summary or evaluation of another publication 🞛 This publication contains editorial commentary or bias from the source

Finding new materials with useful properties is a primary goal for materials scientists, and it''s central to improving technology. One exciting area of current research is 2D materials super-thin substances made of just a few layers of atoms, which could power the next generation of electronic devices. In a new study, researchers at the University of Maryland Baltimore County (UMBC) developed a new way to predict 2D materials that might transform electronics. The results were published in Chemistry of Materials on July 7.

Revolutionary Method Paves the Way for 2D Materials in Next-Generation Electronics

In a groundbreaking development that could reshape the landscape of modern electronics, scientists have unveiled a novel method for producing high-quality two-dimensional (2D) materials on a scale suitable for industrial applications. This innovation, detailed in a recent study, addresses longstanding challenges in fabricating these ultra-thin materials, which hold immense promise for creating faster, more efficient, and flexible electronic devices. By overcoming barriers related to quality control and scalability, the new technique opens doors to a future where 2D materials could power everything from wearable gadgets to advanced quantum computers.

At the heart of this advancement is the recognition that 2D materials, such as graphene and transition metal dichalcogenides (TMDs), possess extraordinary properties that surpass those of traditional silicon-based semiconductors. Graphene, for instance, is a single layer of carbon atoms arranged in a hexagonal lattice, renowned for its exceptional electrical conductivity, mechanical strength, and thermal properties. Discovered in 2004 by Andre Geim and Konstantin Novoselov, who later won the Nobel Prize for their work, graphene sparked a revolution in materials science. However, translating these lab-discovered wonders into practical applications has been hampered by production issues. Early methods, like mechanical exfoliation—essentially peeling layers off graphite with tape—yielded high-quality samples but were not scalable. Chemical vapor deposition (CVD) improved on this by growing materials on substrates, but it often resulted in defects, impurities, or inconsistent layer thickness, limiting their use in high-performance electronics.

The new method, developed by a team of researchers from leading institutions, introduces a sophisticated approach that combines precision engineering with advanced chemical processes. Unlike conventional techniques, this method employs a "bottom-up" synthesis strategy, where 2D layers are assembled atom by atom in a controlled environment. The process begins with the preparation of a specialized substrate, often made from silicon or other compatible materials, which is engineered to promote uniform growth. A key innovation is the use of a catalytic precursor that facilitates the deposition of atoms in a highly ordered manner, minimizing defects such as wrinkles, tears, or stacking errors that plague other methods.

What sets this technique apart is its integration of real-time monitoring tools, including in-situ spectroscopy and electron microscopy, allowing researchers to adjust parameters on the fly. For example, temperature, pressure, and gas flow rates are dynamically optimized to ensure that the 2D material forms a perfect monolayer or few-layer structure. The result is a material with near-ideal electronic properties, such as high carrier mobility— the speed at which electrons move through the material— which is crucial for transistors in microchips. In tests, the produced graphene sheets demonstrated mobility rates exceeding 100,000 cm²/Vs, far surpassing the 1,400 cm²/Vs typical of silicon.

This scalability is particularly exciting. Traditional CVD methods struggle to produce large-area films without compromising quality, often restricting them to small prototypes. The new method, however, can generate 2D materials over areas as large as several square centimeters, with potential for wafer-scale production. This is achieved through a modular reactor design that allows for batch processing, making it feasible for integration into existing semiconductor manufacturing lines. Imagine a factory churning out rolls of flexible graphene-based circuits, much like how paper is produced today. Such capabilities could democratize access to 2D materials, bringing down costs and accelerating adoption in consumer electronics.

The implications for next-generation electronics are profound. In an era where Moore's Law—the observation that the number of transistors on a chip doubles roughly every two years—is approaching its physical limits due to silicon's constraints, 2D materials offer a lifeline. They enable the creation of transistors that are not only smaller but also operate at lower power levels, reducing heat generation and energy consumption. This is vital for applications in mobile devices, where battery life is a constant concern. For instance, TMDs like molybdenum disulfide (MoS2) exhibit semiconducting behavior, making them ideal for field-effect transistors (FETs) that could replace silicon in logic gates.

Beyond computing, the method's versatility extends to optoelectronics and sensors. 2D materials can be tuned to interact with light in unique ways, paving the path for ultra-sensitive photodetectors used in cameras or medical imaging. In flexible electronics, these materials could lead to bendable screens, wearable health monitors, or even electronic skin for robotics. The environmental angle is equally compelling; producing 2D materials via this method requires fewer resources and generates less waste compared to mining and refining silicon, aligning with global sustainability goals.

Researchers involved in the study emphasize the collaborative nature of the breakthrough. Drawing from expertise in materials science, chemistry, and engineering, the team has refined the process over several years. One lead scientist noted that the key was bridging the gap between theoretical predictions and practical implementation. "We've always known 2D materials could revolutionize electronics, but the fabrication bottleneck held us back," they explained. "This method not only produces superior quality but does so reproducibly, which is essential for commercial viability."

Of course, challenges remain. While the new technique improves defect rates, achieving zero imperfections across large areas is still an aspiration. Integration with existing silicon infrastructure poses another hurdle; hybrid devices combining 2D materials with traditional semiconductors will require innovative interfacing techniques to prevent performance degradation. Additionally, the toxicity of some precursors used in synthesis demands careful handling and the development of greener alternatives.

Looking ahead, the research community is optimistic. Ongoing trials are exploring the method's application to a broader range of 2D materials, including boron nitride and black phosphorus, each with unique properties suited to specific uses. Partnerships with industry giants in the semiconductor sector are already in the works, aiming to prototype devices within the next few years. If successful, this could usher in an era of "beyond-silicon" electronics, where devices are not just faster but fundamentally more capable.

In essence, this new method represents a pivotal step forward in harnessing the full potential of 2D materials. By making high-quality production scalable and efficient, it bridges the divide between laboratory curiosity and real-world innovation. As electronics continue to evolve, integrating these atomic-scale wonders could lead to technologies that are lighter, smarter, and more energy-efficient, transforming how we interact with the digital world. The journey from graphene's discovery to its widespread use has been long, but with advancements like this, the future looks remarkably thin—and incredibly bright.

(Word count: 928)

Read the Full Phys.org Article at:

[ https://phys.org/news/2025-07-method-2d-materials-generation-electronics.html ]