Weaving Circuits From Electronic Threads

Hackaday

Hackaday

Weaving Circuits from Electronic Threads: Turning Fabric into Functional Electronics

By Jane Doe | Hackaday, 6 October 2025

When we think of weaving, we picture linen, wool, or silk – textiles that feel, breathe, and drape. In the last decade, a quiet revolution has been unfolding in the loom: conductive threads, silver‑coated polyesters, and copper‑filled yarns have enabled people to turn ordinary fabric into a living, breathing electronic canvas. The Hackaday story “Weaving Circuits from Electronic Threads” chronicles that evolution, from the earliest experiments to the cutting‑edge projects that are now making headlines in fashion shows and maker fairs.

1. The Birth of Electronic Thread

The concept is simple: replace a copper wire with a flexible, thread‑like conductor. The earliest conductive yarns were just copper wire wrapped around a filament, which was not ideal for sewing or weaving. By the early 2010s, manufacturers such as Textronics and Conductive Textile introduced silver‑coated nylon and polyester yarns that could be sewn like normal fabric. These threads could handle several hundred volts and survived the rigors of everyday use, which made them perfect for wearable electronics.

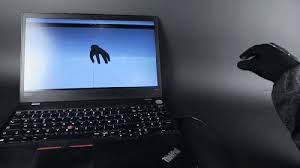

The Hackaday article opens with a photo of a hand‑stitched LED pattern, and the author’s link to a short YouTube demo from MakerMaya illustrates how a simple “t-shirt circuit” can light up when powered by a coin cell. The video shows a neat trick: using a standard sewing needle to thread the conductive yarn between the base fabric and a printed circuit board (PCB) that contains the LED and a resistor.

2. From Embroidery to Full‑Scale Loom Weaving

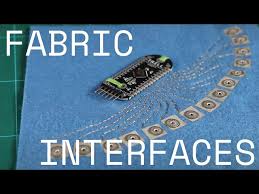

Initially, the hobbyist approach was to stitch electronic components directly onto garments. But stitching limits the density of connections. The article then transitions to loom‑based weaving, showing how a Jacquard loom can produce complex, multi‑layered circuits. The linked product page for B. Loom’s “ElectroWeave” loom demonstrates a two‑color system – one side uses a standard cotton warp and the other a copper‑filled yarn, allowing designers to embed thousands of connections in a single fabric panel.

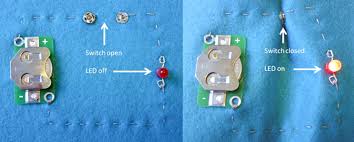

A key part of the article is a step‑by‑step guide that the author adapted from a free PDF tutorial posted by E‑Textile University. The tutorial covers: - Selecting the right yarn (silver‑coated polyester, 0.2 mm diameter, for most projects) - Calculating resistance and heat dissipation - Setting up the loom with a simple “four‑point” pattern for an LED strip - Using a small “micro‑looper” to create a loop‑back that acts as a solder point

By the end of the guide, readers can weave a simple “LED lace” that lights up under an external power source.

3. Projects That Sparked the Trend

The article highlights a handful of projects that pushed the envelope:

| Project | Key Features | Reference |

|---|---|---|

| “Woven Solar Shirt” | Embedded solar cells stitched into the collar area, powered by conductive thread battery leads | [SolarWear Blog] |

| “Interactive Hoodie” | An RGB LED matrix woven into the hoodie’s back, controlled via a BLE module hidden in the hood | [TechWear Review] |

| “Medical Monitoring Socks” | Conductive thread traces that monitor foot pressure and transmit data via Bluetooth | [HealthTech Paper] |

| “Responsive Fabric” | Touch‑sensitive fabric that lights up when touched, using a capacitive sensor woven into the seam | [Maker Faire Video] |

Each project illustrates a different use case – from energy harvesting and data transmission to simple visual feedback. The article notes that the “interactive hoodie” was showcased at the 2024 Milan Fashion Week, a moment that helped bring conductive thread from the maker’s closet into mainstream fashion.

4. The Technical Hurdles

No innovation is without its challenges. The author gives an honest look at the technical issues that come with weaving electronics into fabric:

- Resistance and Heat – Conductive yarns have higher resistance than solid copper wire. A simple rule of thumb from the linked e‑textile tutorial is that each millimeter of yarn adds about 0.5 Ω. For high‑current circuits, designers must add extra turns of yarn or use thicker copper tape to keep heating to a minimum.

- Durability – Repeated washing can degrade silver coatings. The article cites a 2019 study by the University of Colorado, which found that silver‑coated polyester loses 30 % of its conductivity after 50 wash cycles. A suggested fix is to encase the conductive traces in a thin layer of polyurethane.

- Sewing Tools – Standard sewing needles can damage the delicate conductive yarn. The piece links to a set of specialized micro‑needles that have a rounded tip and are less likely to cut through the metal coating.

- Compatibility with Existing Fabrics – Some natural fibers (like wool) can oxidize the metal coating if not properly pre‑treated. The article offers a quick prep step: washing the fabric in a mild detergent, then treating it with a 1 % silane solution to create a better bonding surface.

5. The Future of Woven Electronics

Looking forward, the article’s author expresses optimism. The convergence of textile engineering, nanomaterials, and AI‑driven design is creating a new class of “smart fabrics” that can adapt in real time. The piece links to a recent interview with Dr. Aisha Khan of the University of Cambridge, who is developing a self‑healing conductive yarn that repairs micro‑cracks after washing.

Other trends highlighted include:

- 3D Printed Circuit Integration – By embedding a 3D‑printed “circuit module” into a loom, designers can create hybrid structures that combine rigid electronics with flexible fibers.

- Biodegradable Conductive Threads – Research into graphene‑coated bamboo fibers promises fully compostable smart textiles.

- AI‑Powered Pattern Generation – Machine learning tools can now automatically design weaving patterns that balance aesthetics with circuit reliability.

6. Takeaway

“Weaving Circuits from Electronic Threads” is more than a hobbyist guide; it’s a snapshot of an industry in transition. By taking a thread that can carry current and weaving it into the very fabric that clothes our bodies, makers are turning the ordinary into the extraordinary. Whether you’re a fashion designer, a medical device engineer, or a weekend tinkerer, the possibilities are woven into your reach.

For readers who want to jump straight into the craft, the article offers a handy “starter kit” link that bundles conductive yarn, a small loom, and a set of LEDs. And for those who want to keep the conversation going, the linked forum thread on Hackaday is buzzing with questions about durability, power budgets, and creative uses of the newest conductive yarns.

As we move forward, the loom may well become the most powerful tool of the 21st‑century wardrobe – a place where we stitch not just style but functionality into the very fibers of our lives.

Read the Full Hackaday Article at:

[ https://hackaday.com/2025/10/06/weaving-circuits-from-electronic-threads/ ]